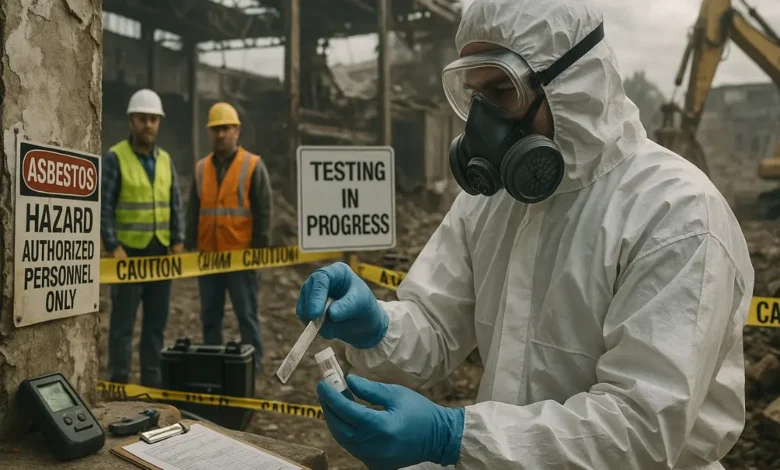

Asbestos Testing During Demolition: What Contractors Must Know

Asbestos testing is a critical step before any demolition project begins, ensuring both worker safety and environmental protection. Contractors play a vital role in identifying, managing, and safely removing asbestos-containing materials before any structure is disturbed. Failing to conduct proper asbestos testing can result in serious health risks, legal consequences, and project delays. Asbestos fibers, when released into the air, can cause long-term illnesses such as mesothelioma and lung cancer. Therefore, understanding the procedures, legal requirements, and responsibilities surrounding asbestos testing is essential for every demolition contractor. We will explore the most important aspects of asbestos testing during demolition projects and the crucial steps contractors must take to stay compliant and safeguard everyone involved.

Key Considerations for Contractors During Asbestos Testing in Demolition

- Understanding the Risks of Asbestos Exposure

Before any demolition work starts, contractors must understand why asbestos is so dangerous. Asbestos was once used in building materials for its durability and heat resistance, but when disturbed, its fibers become airborne and can be inhaled. These fibers are invisible to the naked eye and can stay suspended in the air for hours, increasing the risk of exposure. Contractors must recognize that even minor demolition activities, like drilling or cutting through old walls, can release harmful asbestos fibers. Knowing the health implications helps workers appreciate the importance of strict control measures. Proper training and awareness also ensure that demolition crews act responsibly and follow the correct safety protocols. Recognizing that asbestos hazards are not limited to older buildings but may also appear in mid-20th-century structures helps contractors plan accordingly and avoid unexpected exposure incidents.

- Identifying Materials That May Contain Asbestos

Contractors need to be aware of the many materials that may contain asbestos, particularly in buildings constructed before the year 2000. Common asbestos-containing materials (ACMs) include insulation, floor tiles, cement sheets, roofing materials, pipe lagging, and textured coatings. During demolition, even a small overlooked section can release dangerous fibers. Contractors should rely on a competent asbestos survey to identify and locate these materials before any structure is disturbed. This step ensures that removal teams or licensed asbestos professionals can safely manage the material before demolition proceeds. By recognizing potential ACMs early, contractors reduce the risk of contamination and avoid costly cleanup operations or project shutdowns caused by improper handling.

- Complying with UK Regulations and Legal Duties

In the United Kingdom, strict regulations govern asbestos management and demolition procedures. The Control of Asbestos Regulations 2012 clearly outline a contractor’s legal obligations, including conducting a thorough asbestos survey before demolition begins. Contractors must ensure that a qualified asbestos surveyor performs a “Refurbishment and Demolition Survey,” which is more intrusive than standard inspections. This survey aims to locate all asbestos-containing materials that could be disturbed during demolition. Failing to comply with these regulations can lead to legal action, hefty fines, and reputational damage.

Moreover, the Health and Safety Executive (HSE) requires that all identified asbestos materials be handled by licensed asbestos removal professionals. Understanding and adhering to these regulations not only ensures safety but also protects contractors from penalties and work stoppages. Legal compliance demonstrates professionalism and commitment to health and environmental standards.

- Coordinating with Certified Asbestos Surveyors

One of the most crucial steps contractors must take is coordinating with certified asbestos surveyors. These professionals conduct detailed inspections using sampling and laboratory analysis to confirm the presence of asbestos. Contractors should schedule surveys early in the planning phase to prevent project delays. A collaborative approach allows surveyors to understand the demolition scope and identify areas that require testing. The survey results provide a comprehensive report highlighting the location, type, and condition of asbestos materials.

This report becomes the foundation for developing a safe removal and demolition plan. Contractors should ensure the surveyor they hire is accredited under recognized schemes such as UKAS. Working with accredited professionals guarantees the accuracy of findings and compliance with industry standards. Proper coordination also ensures the demolition team receives the information needed to safely handle or avoid asbestos-containing areas during operations.

- Developing a Safe Asbestos Management and Removal Plan

Once asbestos is identified, contractors must work with licensed asbestos removal companies to design a management and removal plan. This plan should outline procedures for containment, removal, and disposal. It also includes risk assessments and method statements that specify how workers will stay protected. The plan should detail equipment requirements such as protective clothing, respirators, and negative pressure enclosures to prevent fiber release.

Proper communication among the demolition crew is vital to ensure everyone understands their responsibilities. The asbestos removal process must be completed before demolition begins, and air monitoring should confirm the area is safe afterward. Contractors should also ensure asbestos waste is transported and disposed of at authorized facilities. A well-structured asbestos management plan not only ensures compliance but also demonstrates a strong commitment to occupational health and environmental responsibility.

Asbestos testing during demolition is far more than a regulatory requirement—it is a moral and professional responsibility. Contractors who take proactive steps to identify and manage asbestos not only safeguard their teams but also prevent long-term health and environmental harm. From understanding the risks and identifying materials to ensuring compliance with UK laws and maintaining thorough documentation, each step plays an essential role in the process. Effective coordination with certified asbestos surveyors and proper waste management further reinforces safety.